How RFID Tags are Improving Warehouse Operations

In today’s fast-paced supply chain environment, warehouses are under constant pressure to improve efficiency, reduce costs, and optimize inventory management. One of the most innovative technologies helping to achieve these goals is RFID (Radio Frequency Identification) tags. This cutting-edge solution is transforming warehouse operations and providing significant advantages for businesses seeking to streamline their logistics processes.

Streamlining Inventory Management with RFID Tags

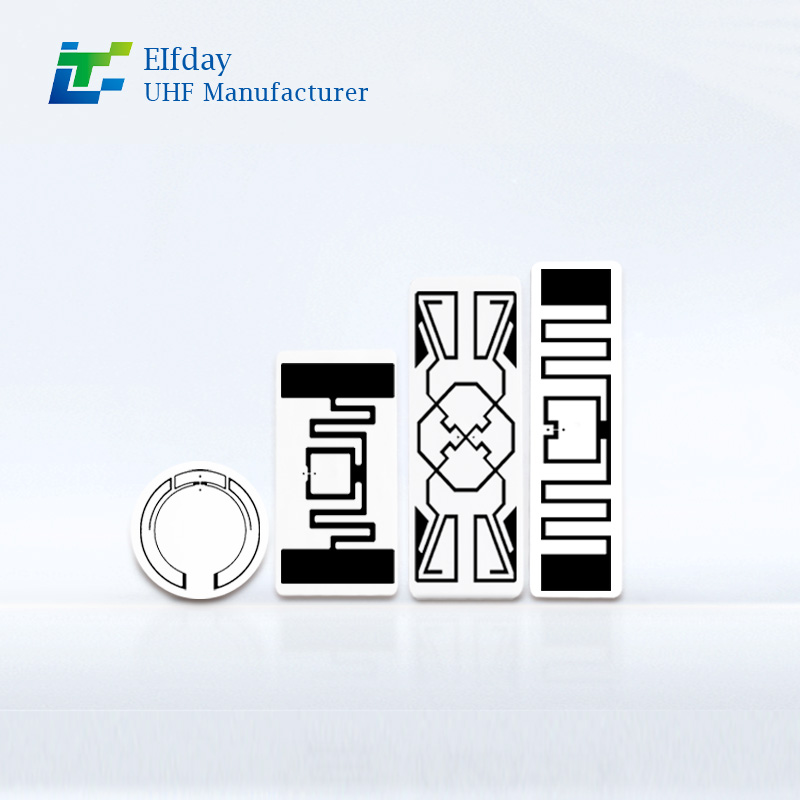

One of the most notable ways RFID tags are improving warehouse operations is by revolutionizing inventory management. Traditionally, warehouses relied on barcode scanning, which required manual scanning of each item. This process is time-consuming and prone to human error. RFID tags, however, enable faster and more accurate inventory tracking. With RFID, a single scan can capture data from multiple items at once, reducing the time spent on inventory checks and ensuring real-time visibility of stock levels.

Moreover, RFID technology provides warehouses with an automated way to track the movement of goods. By attaching RFID tags to products, businesses can continuously monitor their location within the warehouse. This automation not only reduces labor costs but also minimizes the risk of misplaced or lost items, which can cause delays and affect customer satisfaction.

Enhancing Operational Efficiency

RFID tags also play a crucial role in enhancing operational efficiency. With real-time data on inventory levels and the exact location of items, warehouse staff can work more efficiently. This improved visibility allows for better decision-making regarding restocking, order picking, and product handling. For example, RFID-equipped pallets or containers can be quickly identified and routed to the appropriate locations within the warehouse, eliminating time-consuming manual searches.

Additionally, RFID systems help optimize warehouse layout and reduce congestion. By analyzing the data collected from RFID tags, businesses can reorganize their warehouse layout to minimize the distance between frequently picked items, speeding up the order fulfillment process.

Improving Accuracy and Reducing Errors

RFID technology also greatly reduces the likelihood of human error. Traditional inventory tracking methods, such as manual counting or barcode scanning, can be subject to mistakes, especially in high-volume environments. In contrast, RFID tags provide an automated and highly accurate method of tracking inventory, ensuring that data is recorded without the need for manual input. This leads to fewer discrepancies in inventory records and more accurate order fulfillment.

Furthermore, RFID tags can be integrated with warehouse management systems (WMS) to provide seamless communication between physical goods and digital records. This integration ensures that inventory levels are always up to date and allows for better forecasting and planning.

Enhancing Security and Loss Prevention

Another key benefit of RFID tags is their ability to enhance security within warehouses. RFID tags can help track the movement of goods in and out of the facility, providing an additional layer of protection against theft. If an item with an RFID tag is moved without proper authorization, an alert can be triggered, allowing warehouse managers to act quickly.

RFID tags are revolutionizing warehouse operations by improving inventory management, enhancing operational efficiency, reducing errors, and increasing security. As businesses continue to seek ways to optimize their logistics processes, RFID technology presents a powerful solution to meet these demands.

If you’re looking to implement RFID tags in your warehouse operations or want to learn more about how this technology can benefit your business, feel free to reach out. We offer free solutions and expert guidance to help you make the most of RFID technology and improve your warehouse efficiency.