How UHF RFID Stickers Improve Warehouse Efficiency

In today's fast-paced supply chain environment, businesses need solutions that streamline operations, reduce errors, and enhance inventory management. UHF RFID stickers are proving to be game-changers in warehouse efficiency. These small, yet powerful tags are helping companies worldwide reduce costs, improve accuracy, and increase productivity. But how exactly do UHF RFID stickers make a difference in warehouse operations?

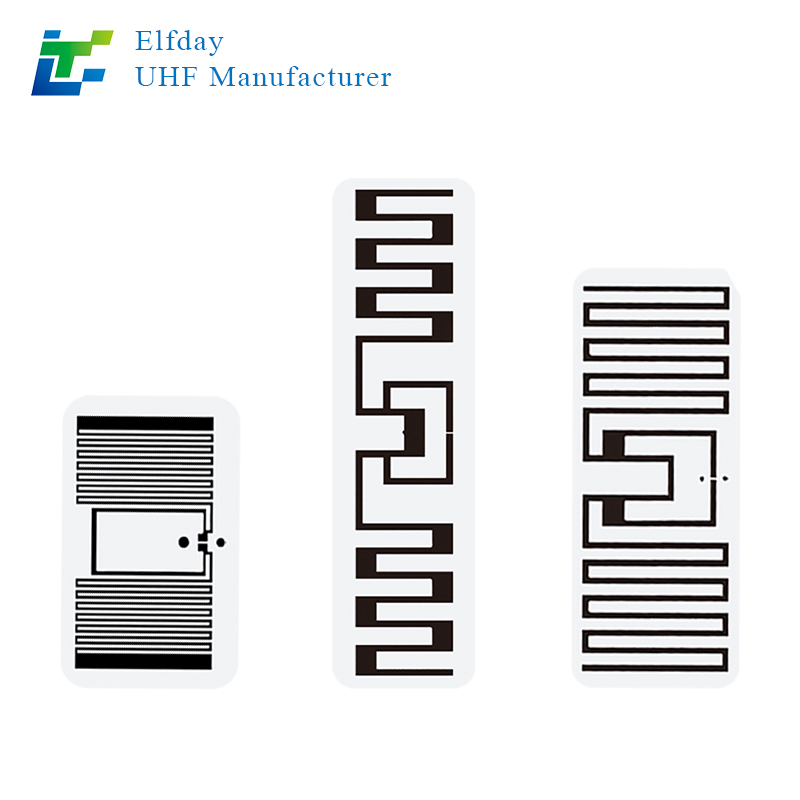

What Are UHF RFID Stickers?

UHF RFID (Ultra High Frequency Radio Frequency Identification) stickers are specialized tags that use radio waves to transmit data about products. These stickers, often attached to items or pallets, can be read from a distance without requiring direct line-of-sight, offering a clear advantage over traditional barcode systems.

By embedding RFID technology into a sticker format, warehouses can easily track inventory, monitor stock movement, and gain real-time visibility into their operations. The benefits are numerous and wide-reaching, from inventory accuracy to operational cost reduction.

Key Ways UHF RFID Stickers Improve Warehouse Efficiency

1. Real-Time Inventory Tracking

Traditional inventory management systems often rely on manual checks or barcode scanning, which can lead to inaccuracies or delays. UHF RFID stickers allow for continuous and real-time tracking of inventory as it moves throughout the warehouse. With RFID readers placed at key locations, warehouse managers can instantly see what is in stock, where it is located, and when items need to be replenished.

2. Enhanced Accuracy

Manual data entry and barcode scanning can often result in human errors, especially during busy periods. UHF RFID stickers reduce the likelihood of such mistakes. Since RFID systems automatically capture data without manual intervention, inventory records are more accurate, minimizing the risk of stockouts, overstocking, or misplaced items.

3. Faster and More Efficient Stocktaking

Stocktaking is a necessary yet time-consuming process for any warehouse. Traditionally, it requires physically scanning each item or pallet. UHF RFID technology streamlines this process by enabling rapid and simultaneous scanning of multiple items at once. With the ability to scan hundreds of items in seconds, UHF RFID stickers drastically reduce the time and labor required for stock audits.

4. Improved Supply Chain Visibility

UHF RFID stickers provide a wealth of data that can be integrated into supply chain management systems. This provides managers with insights into stock levels, product movement, and potential delays in the supply chain. By having access to this critical data in real time, businesses can make informed decisions, reduce bottlenecks, and optimize operations across the entire supply chain.

5. Automated Processes

UHF RFID technology helps automate processes within the warehouse. For instance, when RFID-tagged products pass through certain checkpoints, the system can automatically update inventory records, trigger alerts, or initiate restocking procedures. This automation reduces the need for manual labor and enhances overall productivity.

6. Reduced Loss and Theft

Warehouse loss and theft can be a significant issue, but UHF RFID stickers help mitigate this problem. With RFID-enabled security systems, managers can monitor the movement of goods throughout the facility. If an item is moved without proper authorization, the system will alert managers, allowing them to take immediate action. This reduces shrinkage and enhances security.

The Benefits of UHF RFID Stickers for Your Business

Increased Productivity: By streamlining inventory management and automating key processes, UHF RFID stickers significantly boost productivity within the warehouse. Employees spend less time manually scanning items and more time focusing on other essential tasks.

Cost Savings: Although the initial investment in RFID technology might seem high, the long-term savings are substantial. From reducing labor costs to preventing stock discrepancies and loss, UHF RFID stickers pay for themselves over time.

Scalability: As businesses grow, so do their operational needs. UHF RFID technology is scalable, meaning it can adapt to increasing inventory sizes and warehouse complexity without losing efficiency. Whether you're managing a small warehouse or a large distribution center, RFID can scale with your business.

Why UHF RFID Stickers Are a Smart Investment for Your Warehouse

The logistics and supply chain sectors are increasingly turning to technology to improve efficiency and reduce costs. UHF RFID stickers represent a significant step forward in this evolution. Not only do they improve inventory accuracy and streamline processes, but they also provide real-time insights that can drive better decision-making and optimize warehouse performance.

For businesses looking to stay ahead of the competition, UHF RFID stickers offer a competitive edge in the form of improved warehouse efficiency. If you're ready to elevate your warehouse operations and maximize your efficiency, investing in UHF RFID technology is a step in the right direction.

Incorporating UHF RFID stickers into your warehouse operations can transform how you manage inventory, track goods, and optimize your supply chain. With the ability to automate processes, reduce errors, and enhance overall visibility, UHF RFID technology provides the tools necessary for a more efficient and profitable warehouse. Don’t get left behind—embrace the future of warehouse management with UHF RFID stickers today!