Do UHF RFID Tags Work in Cold Storage?

In the world of logistics and inventory management, the use of UHF RFID tags (Ultra High Frequency Radio Frequency Identification tags) has become increasingly essential. These tags are a powerful tool for tracking assets and products in real-time, but when it comes to cold storage environments, many businesses wonder: Do UHF RFID tags work in cold storage? Let’s explore how these tags perform in such settings and why they are critical for managing inventory in temperatures ranging from freezing to sub-zero levels.

Understanding UHF RFID Tags

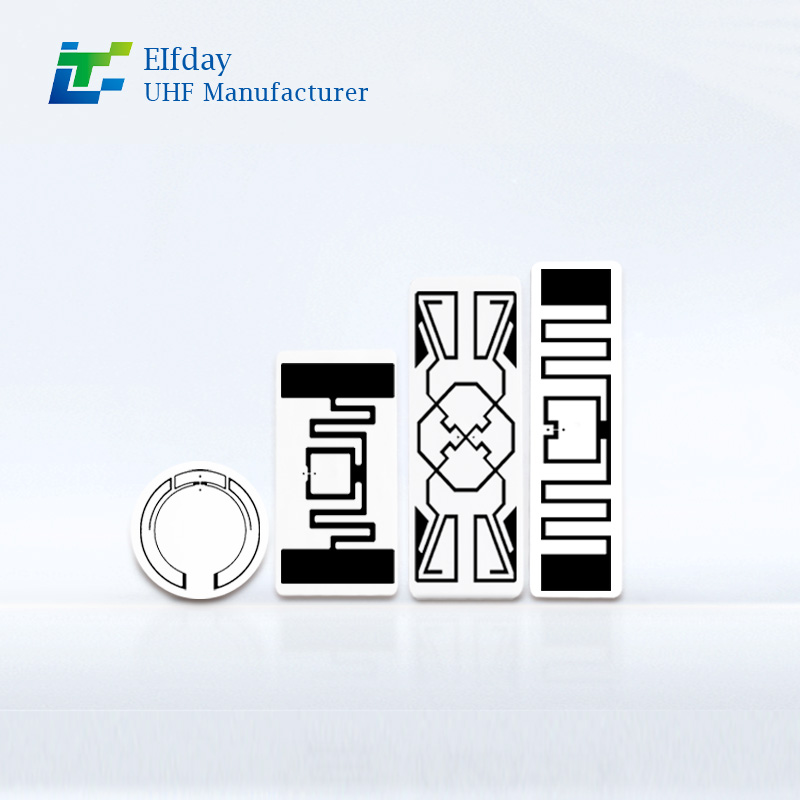

UHF RFID tags are a type of RFID technology that uses radio waves to identify and track objects. They are commonly used in warehouses, manufacturing plants, and retail environments for inventory management. These tags are equipped with small chips and antennas that allow them to communicate with RFID readers to provide real-time data about a product's location, status, and movement.

However, the real question remains: How do UHF RFID tags perform in cold environments like cold storage and freezers?

UHF RFID Tags in Cold Storage: How Do They Perform?

Cold storage facilities are designed to store perishable goods such as food, pharmaceuticals, and chemicals that require low temperatures to maintain their quality. These environments can range from refrigerated spaces with temperatures as low as 4°C (40°F) to freezing temperatures as low as -18°C (0°F) or even lower.

At first glance, it may seem like extreme cold could interfere with the functionality of UHF RFID tags. However, UHF RFID tags are specifically designed to work in a variety of harsh conditions, including cold storage.

1. Resilience of RFID Materials in Cold Environments

Many modern UHF RFID tags are made from durable materials that are capable of withstanding extreme temperatures. The components of these tags, such as the antenna and microchip, are constructed with high-performance materials that can handle freezing temperatures. This means that, unlike older tags or those designed for warmer environments, UHF RFID tags specifically engineered for cold storage applications will continue to perform reliably.

2. Cold-Resistant Packaging for RFID Tags

In addition to the durability of the tag components, cold storage RFID tags often come in specialized packaging that protects them from the cold. This packaging ensures that the tags can continue to operate without suffering damage from condensation, ice formation, or exposure to low temperatures. As such, businesses can rely on these tags to perform consistently in cold storage, from warehouse freezers to refrigerated shipping containers.

3. Radio Frequency Performance in Cold Environments

The radio frequency signals that UHF RFID tags emit can travel through materials like plastic, cardboard, and even thin layers of frost or ice. This makes them suitable for use in cold storage, where traditional barcode scanning might be more challenging due to the cold or the need to open doors to access products. With RFID, inventory tracking is seamless and efficient without compromising on speed or accuracy.

4. Battery Life in Freezing Temperatures

In some cold storage environments, passive UHF RFID tags (those that don’t require a battery) are commonly used for asset tracking. These tags don’t rely on battery power, which is a significant advantage in cold storage environments where temperatures can drain the batteries of other types of sensors. For active RFID tags (those with a battery), many are designed with long-lasting, cold-resistant batteries, ensuring their performance even in freezing temperatures.

Why UHF RFID Tags are a Game Changer in Cold Storage

The ability to track inventory in cold storage with UHF RFID tags offers numerous benefits that improve operational efficiency and reduce costs:

Real-Time Monitoring: RFID technology provides continuous, real-time tracking of products in cold storage, making it easier to monitor inventory levels, temperature, and movement.

Improved Accuracy: Unlike manual barcode scanning, RFID doesn’t require direct line-of-sight, allowing for faster and more accurate data collection.

Reduced Labor Costs: The automation of data collection with RFID reduces the need for manual labor, saving time and minimizing human error.

Enhanced Product Traceability: For industries like food and pharmaceuticals, accurate traceability is critical for ensuring safety and compliance with regulatory standards.

Key Benefits of Using UHF RFID Tags in Cold Storage:

Increased efficiency in managing perishable goods: Track items quickly without needing to manually inspect.

Enhanced visibility of inventory levels: Real-time insights into inventory to reduce stockouts or overstocking.

Reduced risk of human error: Automated tracking eliminates mistakes from manual inventory checks.

Compliance with safety regulations: Helps maintain standards by tracking temperatures and preventing spoilage.

In short, UHF RFID tags are highly effective in cold storage environments. They are built to withstand low temperatures and continue to operate efficiently even in the most challenging conditions. If you are looking to optimize your inventory management in cold storage, UHF RFID tags are an indispensable tool. Their durability, reliability, and ability to provide real-time tracking make them a must-have technology for industries that deal with temperature-sensitive goods.

If you’re ready to improve the efficiency of your cold storage operations, consider investing in high-quality UHF RFID tags that are designed specifically for cold environments. With UHF RFID tags, you can ensure seamless tracking and management of your inventory, no matter the temperature.