Enhancing Supply Chain Efficiency with RFID Tags

In today's fast-paced and highly competitive business environment, supply chain management has become more complex than ever. Companies are constantly looking for ways to streamline operations, improve accuracy, and reduce costs. One of the most effective solutions that has revolutionized the supply chain industry is the integration of RFID tags for supply chain management.

What is RFID and How Does it Work?

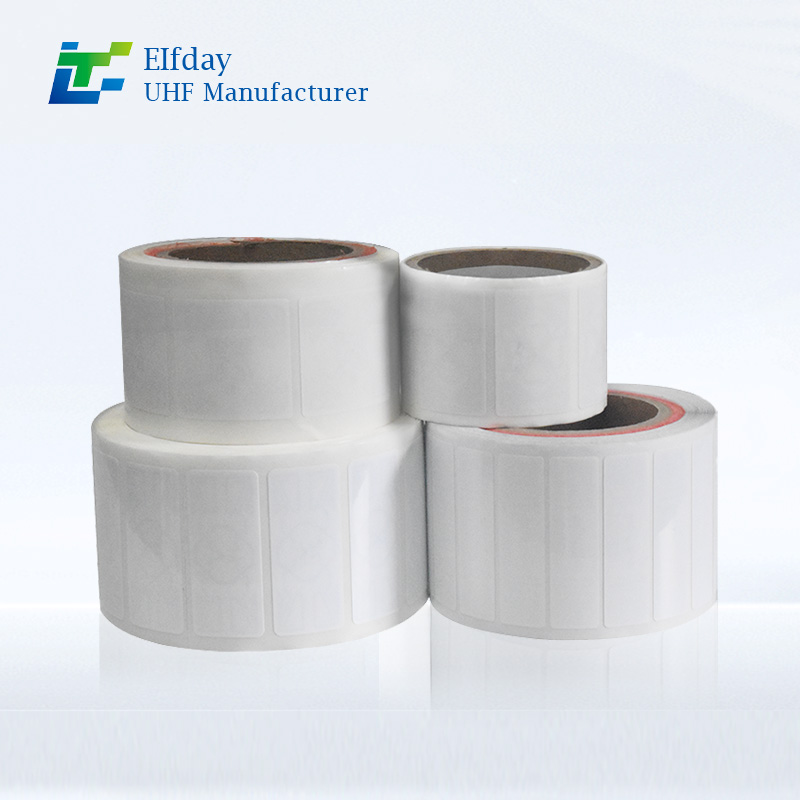

Radio Frequency Identification (RFID) is a technology that uses electromagnetic fields to automatically identify and track tags attached to objects. An RFID system typically consists of a tag, a reader, and a database that records the information transmitted by the tag. The tag contains a microchip that stores data and an antenna that allows the tag to communicate with the reader. This system allows for real-time data collection and visibility across the entire supply chain, making it an invaluable tool for businesses looking to optimize their operations.

Benefits of RFID Tags for Supply Chain

Real-Time Tracking and Visibility

One of the primary advantages of using RFID tags for supply chain is the ability to track goods in real time. With RFID technology, businesses can gain visibility into the location and status of inventory as it moves through various stages of the supply chain, from manufacturing to shipping and delivery. This enables companies to make more informed decisions and respond quickly to any disruptions.

Improved Accuracy and Reduced Errors

Manual inventory management processes are often prone to human errors, leading to inaccuracies in stock levels and delays in shipments. RFID tags provide automated tracking, which significantly reduces the chances of errors caused by manual data entry. This improves overall accuracy and ensures that companies have the right products in the right quantities when they need them.

Enhanced Efficiency and Productivity

RFID technology eliminates the need for manual scanning and barcode scanning, which can be time-consuming and labor-intensive. With RFID tags, items can be automatically tracked and counted without the need for direct line-of-sight, allowing workers to process shipments faster and more efficiently. This leads to improved productivity and reduced labor costs.

Better Inventory Management

Managing inventory is one of the most critical aspects of supply chain management. RFID tags enable businesses to maintain accurate inventory counts and reduce stockouts or overstocking situations. By providing real-time data on inventory levels, RFID technology helps companies optimize their stock levels and improve inventory turnover rates.

Reduced Losses and Theft

With RFID tags, businesses can monitor the movement of goods throughout the supply chain and identify any unauthorized movements or discrepancies. This helps to reduce the risk of theft and loss, which is especially important in industries dealing with high-value goods, such as electronics or pharmaceuticals.

Applications of RFID Tags in the Supply Chain

Warehouse Management

RFID tags are commonly used in warehouse management to improve the accuracy and efficiency of inventory tracking. With RFID, warehouse operators can easily locate products, check stock levels, and manage order fulfillment more efficiently.

Shipping and Logistics

RFID technology plays a crucial role in improving shipping and logistics operations. By attaching RFID tags to shipping containers, businesses can track shipments in real-time, ensuring timely deliveries and reducing the risk of lost or misplaced items.

Manufacturing and Production

In manufacturing, RFID tags help track raw materials, components, and finished products throughout the production process. This allows for better traceability and quality control, ensuring that products meet required standards before they are shipped to customers.

Retail and Consumer Goods

Retailers use RFID tags to streamline the supply chain, from warehouse to store shelves. By incorporating RFID tags into the supply chain, retailers can ensure better stock availability, improve the shopping experience for customers, and reduce the likelihood of stockouts.

Incorporating RFID tags for supply chain management offers significant benefits, including real-time tracking, enhanced accuracy, improved efficiency, and reduced losses. As the demand for faster, more reliable supply chains continues to grow, businesses that adopt RFID technology will be better positioned to stay ahead of the competition and meet customer expectations. With RFID, companies can optimize their operations and create a more efficient and responsive supply chain.