How Warehouse RFID Tags Revolutionize Inventory Management

In today’s fast-paced logistics and retail environments, managing inventory with precision is more critical than ever. Traditional inventory management methods, such as manual stocktaking or barcode scanning, often lead to inefficiencies, human error, and inaccuracies. However, Warehouse RFID Tags have become a revolutionary tool for overcoming these challenges. In this article, we’ll explore how Warehouse RFID Tags are transforming inventory management and why businesses are increasingly adopting this technology.

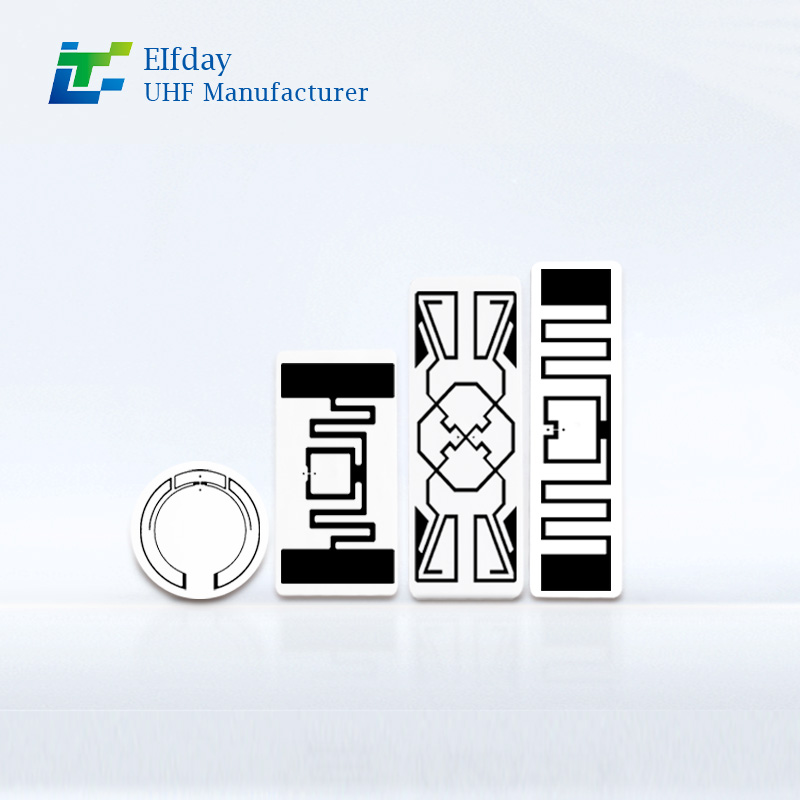

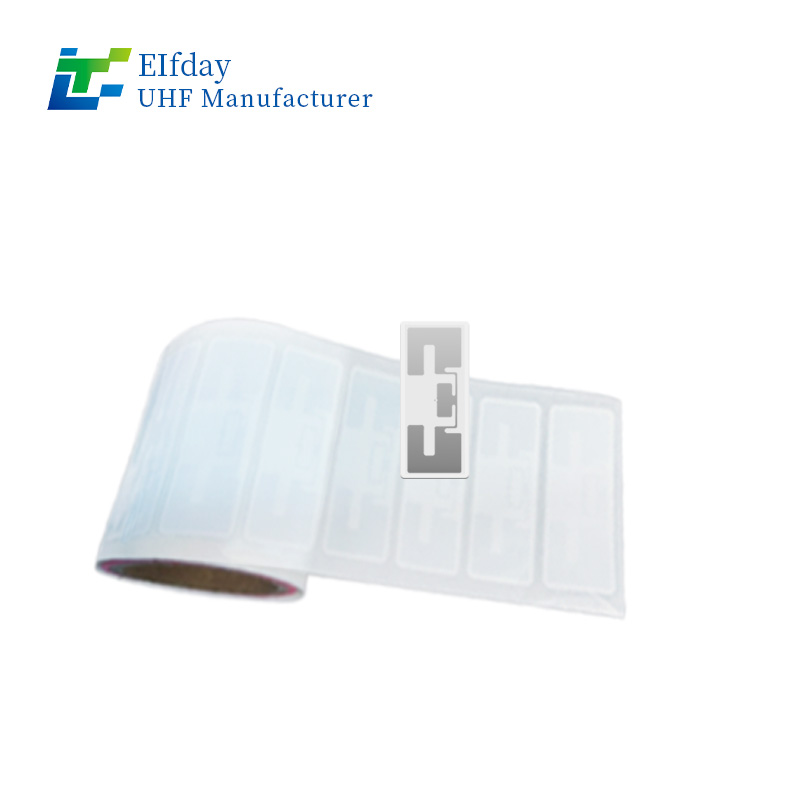

What Are Warehouse RFID Tags?

Warehouse RFID Tags are small, electronic devices that use radio frequency to automatically identify and track items in a warehouse. These tags contain a microchip with a unique identifier, and when they come into contact with an RFID reader, they transmit data that can be used to monitor and manage inventory. Unlike traditional barcode systems, RFID tags do not require direct line-of-sight to be read, making them highly efficient for warehouse operations.

How Warehouse RFID Tags Revolutionize Inventory Management

Enhanced Accuracy and Reduced Human Error

One of the biggest challenges in inventory management is ensuring accuracy. Manual stock counting and barcode scanning are prone to human error, often leading to discrepancies between actual stock levels and recorded data. With Warehouse RFID Tags, businesses can automate the inventory process. RFID systems update inventory data in real time, drastically reducing the risk of errors and improving inventory accuracy.

Real-Time Inventory Tracking

The ability to track inventory in real time is another game-changing advantage of Warehouse RFID Tags. Traditionally, warehouses rely on periodic manual stock checks, which can cause delays and inaccuracies in stock levels. With RFID, each item is automatically tracked as it moves through the warehouse, giving managers real-time visibility into inventory levels. This real-time data allows businesses to make faster decisions and respond quickly to stock-outs, overstocking, or misplaced items.

Increased Efficiency and Speed

Warehouse operations can be slow and labor-intensive without automation. Warehouse RFID Tags enable businesses to speed up processes like receiving, stocking, and picking. RFID systems can read multiple tags at once, allowing workers to scan large batches of items in seconds. This eliminates the need for individual barcode scanning and significantly reduces the time spent on inventory management tasks. As a result, warehouses can handle more items in less time, increasing operational efficiency.

Improved Stock Management and Reduced Losses

Managing stock effectively is vital for any business, but with traditional methods, inventory errors can lead to stock discrepancies or lost items. Warehouse RFID Tags provide a more secure and reliable method for tracking items from receipt to dispatch. RFID systems make it easier to track product movements, and they can even alert warehouse staff if stock is misplaced or stolen. This added level of security helps reduce shrinkage and ensures that items are always accounted for.

Better Asset Utilization

With Warehouse RFID Tags, businesses can track the movement and condition of assets in real time. This data allows for better asset utilization and planning, as managers can monitor the lifecycle of inventory items and make decisions based on up-to-date information. This also helps prevent overstocking and understocking, as RFID systems provide accurate data on when to reorder stock and when to clear out excess items.

Benefits of Warehouse RFID Tags in Warehouse Operations

Faster and More Accurate Stocktaking: RFID eliminates the need for manual counting and scanning, speeding up the stocktaking process and reducing errors.

Real-Time Data for Better Decision Making: Managers can view live inventory data to make informed decisions about stock levels, product placement, and reordering.

Reduced Labor Costs: Automation reduces the time spent on manual tasks, allowing warehouse staff to focus on higher-value activities, thus reducing overall labor costs.

Improved Customer Satisfaction: With more accurate and up-to-date inventory, customers are more likely to receive the right products on time, improving overall satisfaction.

Scalability: Warehouse RFID Tags are highly scalable, making them suitable for small warehouses as well as large, multi-location operations.

Applications of Warehouse RFID Tags

Warehouse RFID Tags are used across various industries for improving inventory management, including:

Retail: Retailers use RFID tags to track inventory across multiple locations and improve stock availability, ensuring customers always have access to the products they need.

Manufacturing: In manufacturing, RFID tags help track raw materials, components, and finished goods through the production process, improving supply chain visibility and reducing delays.

Logistics and Distribution: In logistics, RFID tags enable faster, more efficient tracking of shipments, reducing the time it takes to verify inventory and speeding up distribution.

Pharmaceuticals and Healthcare: Warehouse RFID Tags play a crucial role in the pharmaceutical and healthcare sectors by ensuring inventory is accurately tracked and managed in compliance with regulations.

Why Warehouse RFID Tags Are Essential for the Future of Inventory Management

As the demand for faster and more accurate inventory management grows, Warehouse RFID Tags are becoming an essential tool for businesses looking to stay competitive. RFID technology provides a level of automation and efficiency that traditional methods simply cannot match. By adopting RFID, warehouses can not only streamline their operations but also significantly improve inventory accuracy, reduce operational costs, and increase customer satisfaction.

Warehouse RFID Tags are revolutionizing inventory management by offering businesses a more accurate, efficient, and cost-effective way to track their stock. With the ability to provide real-time inventory data, reduce human error, and improve operational efficiency, RFID is quickly becoming the go-to solution for modern warehouses. Whether you're looking to enhance your inventory accuracy or streamline your warehouse operations, investing in Warehouse RFID Tags will give your business the competitive edge it needs to succeed in the digital age.