Leveraging RFID Tags for Cold Chain Management

Cold chain management is crucial for industries such as pharmaceuticals, food, and healthcare, where products must be kept at specific temperatures to ensure their quality, safety, and effectiveness. Maintaining the integrity of the cold chain requires real-time monitoring and precise tracking of products from the point of origin to the final destination. RFID tags for cold chain management have emerged as a transformative solution, enabling companies to enhance visibility, ensure compliance, and reduce losses.

What is Cold Chain Management?

Cold chain management refers to the process of transporting, storing, and handling temperature-sensitive products under controlled conditions. It involves monitoring and maintaining a specific temperature range throughout the supply chain to prevent spoilage, degradation, or contamination. This is especially important for perishable goods, such as fresh produce, meat, dairy products, vaccines, and medicines, which can lose their effectiveness or become unsafe if exposed to temperature fluctuations.

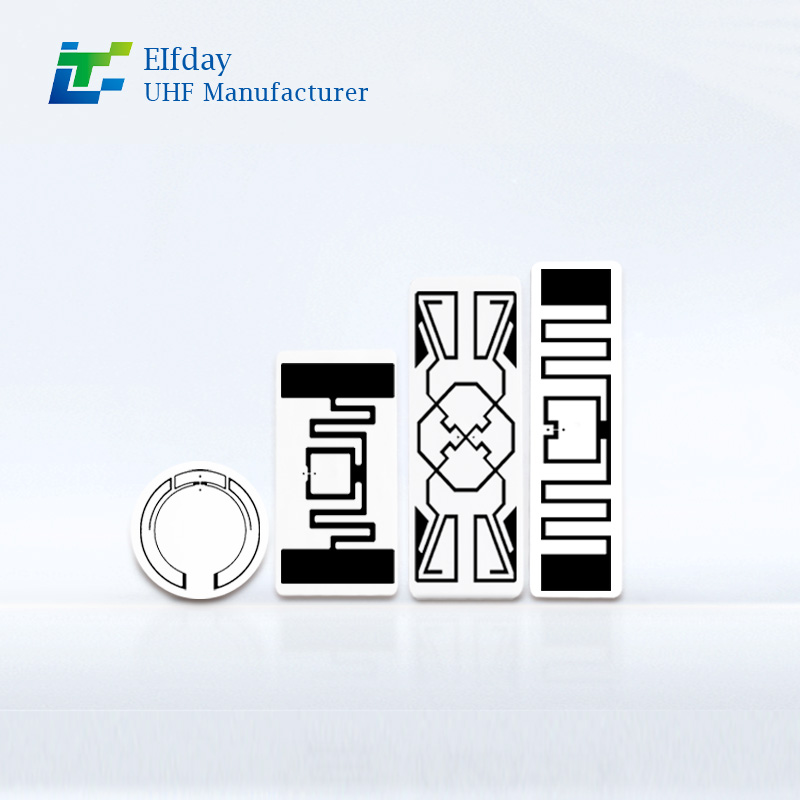

The Role of RFID Tags in Cold Chain Management

Radio Frequency Identification (RFID) tags are small, electronic devices that use radio waves to transmit information. In cold chain management, RFID tags are used to monitor and track products as they move through the supply chain. These tags are attached to individual items or packaging and can store vital information such as temperature, location, and product details. The integration of RFID tags for cold chain management offers numerous benefits that can improve the overall efficiency and effectiveness of temperature-controlled logistics.

Key Benefits of RFID Tags for Cold Chain Management

Real-Time Temperature Monitoring

One of the most significant challenges in cold chain management is maintaining consistent temperatures throughout the supply chain. RFID tags for cold chain management are equipped with temperature sensors that can continuously monitor the temperature of a product or shipment. This data is transmitted in real-time, allowing companies to ensure that products are kept within the required temperature range throughout the journey. If a temperature deviation occurs, the system can trigger alerts, allowing for immediate corrective actions.

Improved Traceability and Transparency

RFID technology enables businesses to track the exact location and condition of their products at any given time. With RFID tags for cold chain management, companies gain full visibility into the movement of goods, from the moment they leave the warehouse to when they reach the end customer. This transparency helps ensure compliance with industry standards and regulatory requirements, providing detailed records of the product's journey and temperature history.

Reduced Risk of Spoilage and Loss

Temperature-sensitive goods, such as vaccines and perishable foods, are highly vulnerable to spoilage if they are exposed to inappropriate conditions. Using RFID tags to monitor temperature fluctuations in real-time helps reduce the risk of product spoilage, loss, or waste. This not only saves money but also protects the integrity of the product and ensures that customers receive high-quality goods.

Automated Data Collection and Reporting

Traditional cold chain management often involves manual data entry and record-keeping, which can be time-consuming and error-prone. With RFID tags, data is automatically collected and transmitted to the central system, eliminating the need for manual tracking and paperwork. This automation simplifies the process of monitoring temperature and location, saving time and reducing human errors.

Regulatory Compliance

Many industries, particularly pharmaceuticals and food, are subject to strict regulatory standards that require temperature-controlled transport and storage. RFID tags for cold chain management help companies meet these regulations by providing accurate, time-stamped temperature data. This ensures that businesses can demonstrate compliance during audits and inspections, reducing the risk of penalties and improving trust with customers and regulators.

Applications of RFID Tags in Cold Chain Management

Pharmaceuticals and Healthcare

In the pharmaceutical industry, maintaining the cold chain is critical to ensuring the efficacy of vaccines, biologics, and other temperature-sensitive drugs. RFID tags for cold chain management enable real-time tracking of these products, ensuring they remain within the required temperature range and arrive at their destination in optimal condition. This helps prevent costly product recalls and maintains patient safety.

Food and Beverage Industry

For the food and beverage industry, RFID tags for cold chain management play a key role in ensuring the safe transportation of perishable items like dairy, meat, and seafood. Temperature deviations can lead to contamination and spoilage, which can have serious consequences for consumer health. RFID tags help companies monitor and control temperatures during transportation and storage, ensuring that products meet safety standards and remain fresh.

Logistics and Distribution

In logistics, RFID tags help streamline the management of temperature-sensitive shipments. By attaching RFID tags to pallets or shipping containers, logistics companies can track shipments in real-time, monitor their temperature, and optimize routes to minimize delays. This improves efficiency and reduces the risk of disruptions to the cold chain.

Retailers and Grocery Chains

Retailers and grocery chains can also benefit from RFID tags for cold chain management. These tags ensure that perishable goods, such as frozen foods and refrigerated items, maintain proper storage conditions during transit from distribution centers to retail locations. With RFID technology, stores can better manage their inventory and reduce waste due to spoilage.

The use of RFID tags for cold chain management has revolutionized the way businesses track and monitor temperature-sensitive goods. By providing real-time temperature monitoring, improving traceability, reducing spoilage, and ensuring regulatory compliance, RFID tags are an essential tool for companies looking to optimize their cold chain operations. As the demand for safe, high-quality products continues to rise, RFID technology will play an increasingly important role in maintaining the integrity of temperature-sensitive goods across industries.