Maximizing Efficiency with UHF RFID Tags in Manufacturing

In today’s fast-paced manufacturing environment, optimizing operational efficiency is crucial for maintaining competitiveness. One of the most transformative technologies helping businesses achieve this goal is UHF RFID tags. By integrating UHF RFID tags into manufacturing processes, companies can enhance productivity, streamline inventory management, and reduce operational costs. This article explores the numerous benefits of UHF RFID tags in manufacturing and how they can significantly improve your operations.

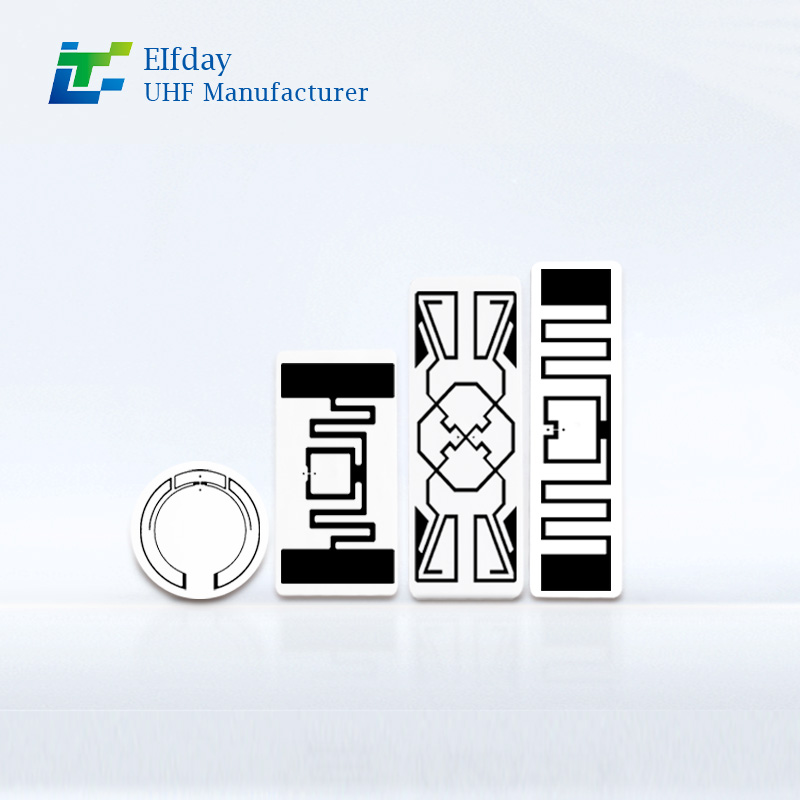

What Are UHF RFID Tags?

UHF (Ultra High Frequency) RFID (Radio Frequency Identification) tags are advanced identification tools that use radio waves to communicate data between the tag and an RFID reader. These tags operate at a frequency between 860 MHz and 960 MHz, providing long-range capabilities that make them ideal for industrial and manufacturing environments. Unlike traditional barcodes, UHF RFID tags offer the advantage of being read remotely without the need for line-of-sight, which greatly speeds up the process of inventory tracking and asset management.

Streamlining Inventory and Asset Management

One of the most significant challenges in manufacturing is keeping track of raw materials, components, and finished products. With UHF RFID tags, businesses can instantly locate and manage inventory without manual scanning. This automation not only saves time but also reduces human error, ensuring that the right materials are always in the right place at the right time.

By utilizing UHF RFID tags for inventory control, manufacturers can achieve:

Real-time tracking: Monitor the movement of goods throughout the supply chain, from raw material acquisition to finished product shipping.

Improved accuracy: Eliminate errors associated with manual data entry or barcode scanning, leading to more accurate inventory records.

Reduced labor costs: Automate inventory management, allowing workers to focus on higher-value tasks.

Enhancing Manufacturing Efficiency

UHF RFID tags can also optimize manufacturing workflows by enabling better visibility into the production process. By tagging machinery, tools, and work-in-progress items, manufacturers can gain real-time insights into the status of their operations. This data helps streamline production schedules, avoid bottlenecks, and ensure that resources are being used efficiently.

Increased visibility allows for:

Preventive maintenance: By monitoring the usage and performance of machinery, manufacturers can predict when maintenance is needed, reducing unexpected downtime.

Enhanced quality control: Tracking individual components throughout the production process ensures that defective items are identified early, reducing waste and rework.

Improved worker safety: With UHF RFID tags, it’s easier to track the movement of materials and tools, reducing the likelihood of accidents or misplaced items.

UHF RFID Tags and Supply Chain Optimization

The supply chain is another area where UHF RFID tags have a transformative impact. By incorporating RFID technology into logistics operations, manufacturers can track goods across multiple locations with greater accuracy and speed. This leads to a more streamlined supply chain, reducing delays and ensuring that products are delivered on time.

Key benefits include:

Faster processing times: Items can be quickly scanned without stopping to manually check barcodes, speeding up the flow of goods.

Better visibility: Real-time tracking ensures that businesses always know the exact location of goods in transit, reducing the chances of loss or misdirection.

Increased customer satisfaction: With faster, more accurate deliveries, manufacturers can meet customer demands more effectively, leading to stronger relationships and repeat business.

Reducing Costs with UHF RFID Tags

While the initial investment in UHF RFID tags and associated infrastructure may seem high, the long-term cost savings far outweigh the upfront expenditure. By automating key processes such as inventory management and equipment tracking, manufacturers can significantly reduce operational costs.

Savings come from:

Reduced inventory holding costs: By ensuring accurate, real-time tracking, businesses can avoid overstocking or stockouts, leading to better inventory turnover.

Lower labor costs: Automation reduces the need for manual labor, allowing companies to reallocate workers to higher-value tasks.

Fewer lost or misplaced items: With UHF RFID tags, the risk of lost assets is minimized, reducing the need to replace items and avoidable downtime.

Why Invest in UHF RFID Tags for Your Manufacturing Business?

Incorporating UHF RFID tags into your manufacturing operations is not just a technological upgrade—it’s a strategic move that can significantly improve efficiency, reduce costs, and enhance customer satisfaction. From improving inventory management to streamlining the supply chain, the benefits of UHF RFID tags are clear.

If you’re looking to stay ahead of the competition, now is the time to integrate UHF RFID tags into your manufacturing processes. Whether you're looking to boost operational efficiency or reduce errors, this technology offers an undeniable competitive advantage that can help future-proof your business.

By making the investment today, you’re setting the foundation for a more efficient and profitable manufacturing operation tomorrow.