Reducing Losses with RFID UHF Anti-Liquid Tags for Bottles

In today’s competitive market, inventory control and loss prevention are crucial to business success, especially in industries dealing with valuable products like beverages and liquids. RFID UHF Anti-Liquid Tags for Bottles offer a transformative solution for businesses seeking to reduce product losses and enhance supply chain efficiency. These tags are designed specifically to address the unique challenges faced by the beverage and liquid packaging industries, providing businesses with a secure and efficient way to track bottles, reduce theft, and ensure product integrity.

The Challenge: Losses in Bottle Management

Losses in bottle management can arise from a variety of factors: theft, spillage, contamination, and errors in inventory tracking. For businesses in the beverage, pharmaceutical, and even cosmetics sectors, managing bottled goods presents a significant challenge. Bottles are often handled multiple times during the supply chain, from manufacturing to storage and distribution. Without an efficient tracking system, bottles are susceptible to theft or mishandling, resulting in significant financial losses.

Traditional inventory management methods are often unreliable, prone to human error, and difficult to scale. As the need for accurate tracking grows, businesses must seek smarter solutions that not only reduce losses but also streamline operations.

How RFID UHF Anti-Liquid Tags Work

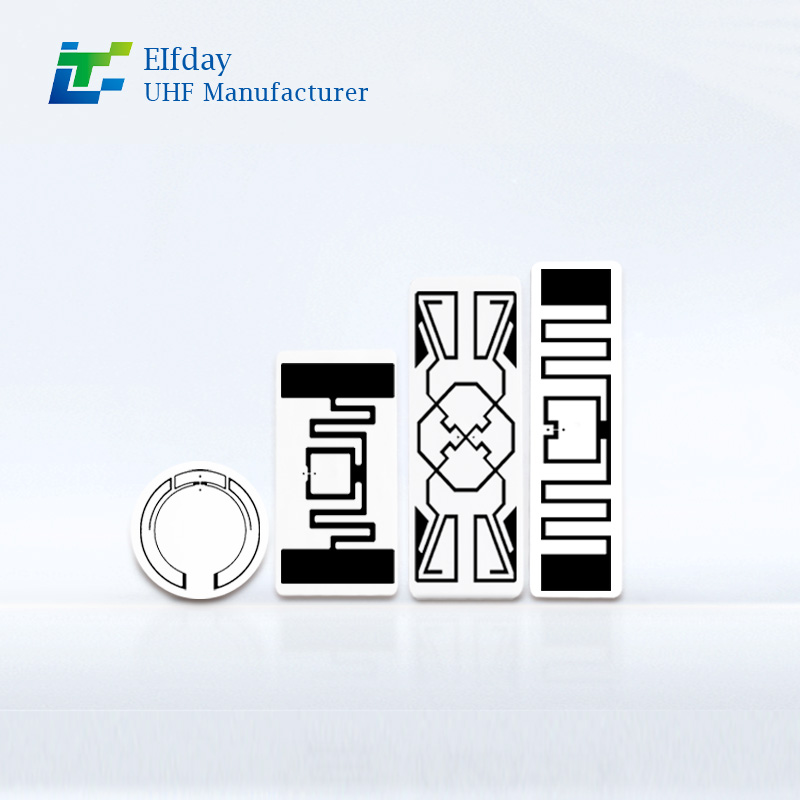

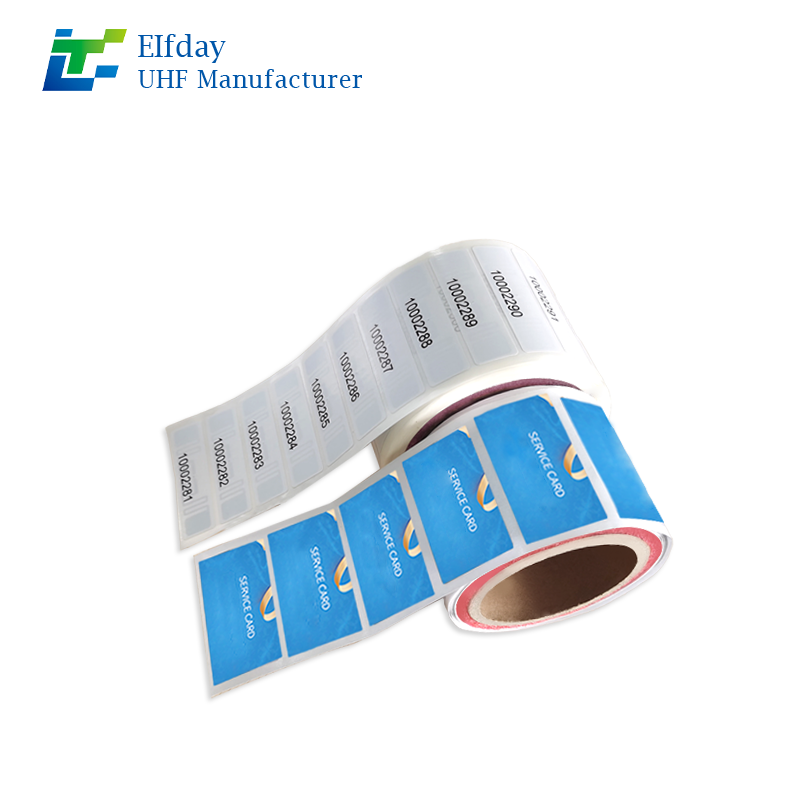

RFID UHF Anti-Liquid Tags for Bottles are the latest in advanced inventory management technology. UHF (Ultra High Frequency) RFID tags offer a longer read range and faster processing times, making them ideal for high-volume tracking of bottles across long distances. Unlike traditional barcode systems, RFID tags do not require direct line-of-sight, allowing for faster scanning and less manual labor.

The anti-liquid feature is particularly important for the beverage industry, where bottles are often exposed to moisture and liquids. These specialized RFID tags are designed to withstand these conditions, ensuring that they remain readable and functional, even in wet environments. This durability reduces the risk of tag failure, ensuring that your bottles can be tracked accurately and efficiently, no matter the conditions.

The Benefits of RFID UHF Anti-Liquid Tags for Bottles

Enhanced Inventory Accuracy

With RFID UHF Anti-Liquid Tags for Bottles, businesses can achieve real-time inventory visibility. The tags allow for automatic updates on stock levels and movements, reducing the chance of errors in inventory counts. This accuracy ensures that businesses can quickly identify discrepancies, minimizing losses due to miscounts or misplaced bottles.

Prevention of Theft and Tampering

One of the most significant advantages of RFID UHF Anti-Liquid Tags is their ability to prevent theft and tampering. The unique identification of each tag makes it easy to monitor bottles throughout the supply chain. If a bottle is removed from its designated area or tampered with, an alert can be triggered, notifying security personnel or management.

Faster and More Efficient Supply Chain

RFID tags enable faster processing times during shipment, receiving, and inventory audits. The ability to quickly scan multiple bottles simultaneously, without the need for direct line-of-sight, speeds up warehouse operations. This increased efficiency allows businesses to process more orders in less time, improving customer satisfaction and reducing operational costs.

Improved Product Integrity

In industries such as pharmaceuticals and beverages, the integrity of the product is paramount. RFID UHF Anti-Liquid Tags ensure that bottles are not exposed to contamination or unauthorized handling. With detailed tracking, businesses can guarantee that their products reach customers in the best condition, reducing the risk of damaged or tampered goods.

Cost Savings Over Time

While the initial investment in RFID technology may seem high, the long-term savings are significant. By reducing losses, preventing theft, and improving operational efficiency, businesses can achieve a high return on investment (ROI). Furthermore, the ability to optimize inventory management means fewer stockouts, reducing the need for overstocking and thus lowering storage costs.

Why Choose RFID UHF Anti-Liquid Tags for Bottles?

Choosing the right RFID tags for bottle tracking is crucial to improving your business's bottom line. RFID UHF Anti-Liquid Tags for Bottles are specifically designed to meet the unique challenges of liquid packaging industries. Their durability in wet conditions, long read range, and ease of integration into existing systems make them a top choice for businesses looking to optimize their supply chain and reduce losses.

By incorporating RFID technology into your bottle management system, you not only improve security but also streamline operations. The real-time data provided by RFID tags allows businesses to make informed decisions, respond quickly to inventory issues, and maintain a high level of product quality control.

RFID UHF Anti-Liquid Tags for Bottles offer businesses a powerful solution for reducing losses and improving efficiency. Whether you’re in the beverage, pharmaceutical, or cosmetics industry, these RFID tags provide a secure, accurate, and efficient way to manage your bottle inventory. With the added benefits of preventing theft, enhancing product integrity, and optimizing your supply chain, it’s clear that RFID UHF Anti-Liquid Tags are an essential tool for businesses looking to stay competitive in today’s fast-paced market.

Start reducing your losses and enhancing your bottle tracking system today with RFID UHF Anti-Liquid Tags for Bottles. Contact us to learn more and take the first step toward smarter inventory management.