Unlock the Full Potential of Warehouse Management with UHF RFID Tags

In the fast-paced world of logistics and warehousing, efficiency is key to staying competitive. Traditional inventory management methods, such as barcode scanning, are being replaced by more advanced technologies to improve speed, accuracy, and automation. One of the most effective innovations in this space is UHF RFID tags for warehouse management. This technology offers several key benefits that can help businesses optimize their warehouse operations and enhance overall efficiency.

In this article, we will explore how UHF RFID tags are transforming warehouse management and how adopting this technology can unlock the full potential of your warehouse operations.

What Are UHF RFID Tags and How Do They Work?

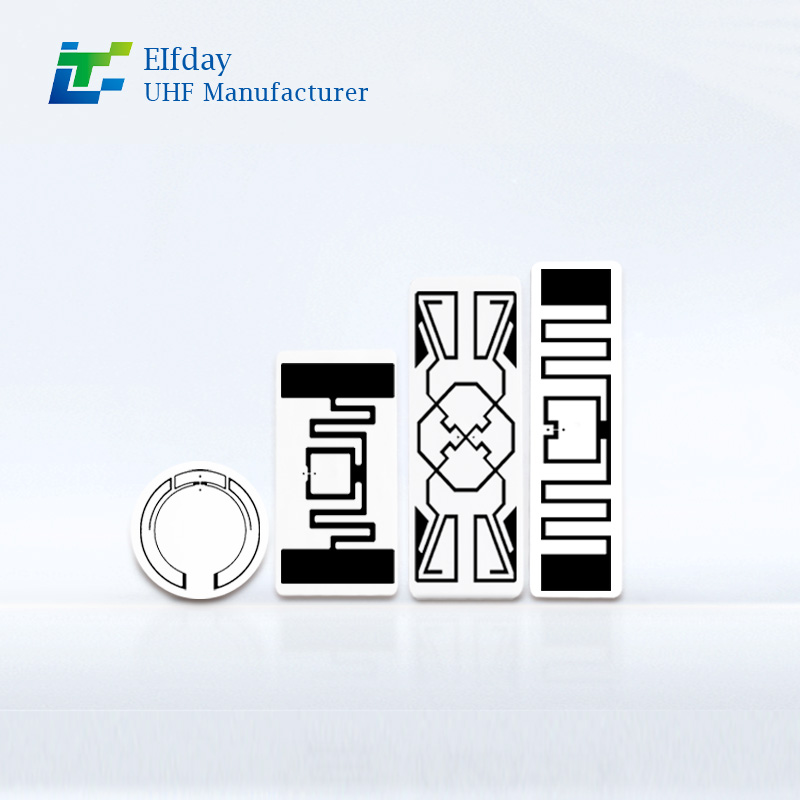

UHF RFID tags for warehouse management are advanced tracking devices that use radio frequency to communicate data between a tag and a reader. These tags are attached to items, pallets, or containers in the warehouse, storing information such as product IDs, location data, and other relevant details. UHF (Ultra High Frequency) RFID technology operates at frequencies between 860-960 MHz, allowing the tags to be read from longer distances and providing faster data transmission than traditional RFID tags.

In a warehouse environment, UHF RFID tags for warehouse management can be used for a wide range of applications, including tracking inventory, managing assets, and ensuring the accuracy of stock levels.

Key Benefits of UHF RFID Tags for Warehouse Management

Increased Accuracy and Efficiency

One of the main advantages of UHF RFID tags for warehouse management is the dramatic improvement in inventory accuracy. Unlike barcode scanning, which requires line-of-sight, UHF RFID tags can be read from a distance without the need for direct visual contact. This means that warehouse workers can quickly scan multiple items at once, even if they are stored in high shelves or stacked together. As a result, stocktaking is faster and more accurate, reducing the chance of human error.

Real-Time Inventory Tracking

With UHF RFID tags for warehouse management, warehouses can achieve real-time tracking of inventory levels. RFID readers can capture data automatically as goods are moved in and out of the warehouse, providing up-to-the-minute updates on stock levels. This eliminates the need for manual stock checks and helps warehouse managers make informed decisions quickly, preventing stockouts or overstocking.

Faster Warehouse Operations

The speed at which UHF RFID tags for warehouse management operate makes them ideal for high-volume warehouses. RFID readers can scan large quantities of tags simultaneously, eliminating the need to scan each item individually. This results in faster order fulfillment, quicker restocking, and improved overall warehouse productivity.

Reduced Labor Costs

By automating the process of tracking inventory and assets, UHF RFID tags for warehouse management reduce the amount of manual labor required for stock-taking, asset management, and inventory reconciliation. This reduces labor costs and allows warehouse staff to focus on more value-added tasks, such as picking and packing orders or improving customer service.

Enhanced Security and Theft Prevention

UHF RFID tags for warehouse management also provide enhanced security by offering the ability to track high-value items or sensitive goods. RFID systems can alert warehouse managers if an item is moved without authorization, helping prevent theft or loss. This is especially useful in high-security environments, where accurate tracking and real-time monitoring are critical.

Improved Warehouse Workflow

By integrating UHF RFID tags for warehouse management with your warehouse management system (WMS), you can streamline workflows and improve operational efficiency. Data collected by RFID readers can be directly fed into the WMS, providing a centralized system for managing inventory, orders, and shipments. This integration allows for better coordination between departments and faster response times.

Why UHF RFID Tags are Essential for Modern Warehouse Management

As businesses face increasing pressure to meet customer demands and improve operational efficiency, UHF RFID tags for warehouse management are becoming a crucial tool in achieving these goals. Here are some reasons why UHF RFID technology is essential for modern warehouse systems:

Longer Read Range: Unlike traditional RFID tags, UHF RFID tags for warehouse management can be read from several meters away. This allows for greater flexibility and efficiency in scanning large volumes of items without requiring close proximity to the reader.

Durability: UHF RFID tags for warehouse management are designed to withstand harsh environments, including extreme temperatures, moisture, and physical damage. Whether your warehouse stores perishable goods or heavy machinery, UHF RFID tags can endure challenging conditions.

Scalability: Whether you're managing a small warehouse or a large multi-location facility, UHF RFID tags for warehouse management can scale to meet the needs of any operation. The technology is flexible and can grow with your business, adapting to new items, locations, and assets as required.

How to Implement UHF RFID Tags for Warehouse Management

Implementing UHF RFID tags for warehouse management can seem like a significant investment, but the benefits it brings to your operations are well worth it. Here are the key steps to consider when implementing RFID technology:

Select the Right UHF RFID Tags

Choose the appropriate type of RFID tags based on your warehouse needs. Passive tags are the most common and cost-effective, while active tags are ideal for high-value or moving assets that require long-range tracking.

Install RFID Readers

Place RFID readers strategically throughout the warehouse to ensure comprehensive coverage. This will allow your system to capture data from all items, regardless of their location in the facility.

Integrate with Your Warehouse Management System (WMS)

To maximize the benefits of UHF RFID tags for warehouse management, integrate the RFID system with your existing WMS. This will allow for automatic updates of inventory levels, improve order processing, and enable real-time tracking of goods.

Train Staff on RFID Technology

Training your warehouse staff is crucial to ensure the system is used effectively. Provide training on how to use RFID readers, interpret data, and troubleshoot common issues.

UHF RFID tags for warehouse management offer a powerful solution for businesses looking to improve inventory control, speed up operations, and reduce costs. By automating asset tracking and providing real-time data, RFID technology enables warehouse managers to make better-informed decisions and streamline workflows. As your warehouse grows and evolves, UHF RFID technology will play a key role in maintaining efficiency, improving accuracy, and staying ahead of the competition.

Start integrating UHF RFID tags for warehouse management today, and unlock the full potential of your warehouse operations.