Unlocking Efficiency in Logistics with RFID Tags

In the fast-paced world of logistics, efficiency, accuracy, and speed are paramount. From inventory management to real-time tracking, logistics companies are continually looking for ways to streamline their operations and reduce costs. One technology that is transforming the logistics industry is RFID (Radio Frequency Identification) tags.

What Are RFID Tags and How Do They Work in Logistics?

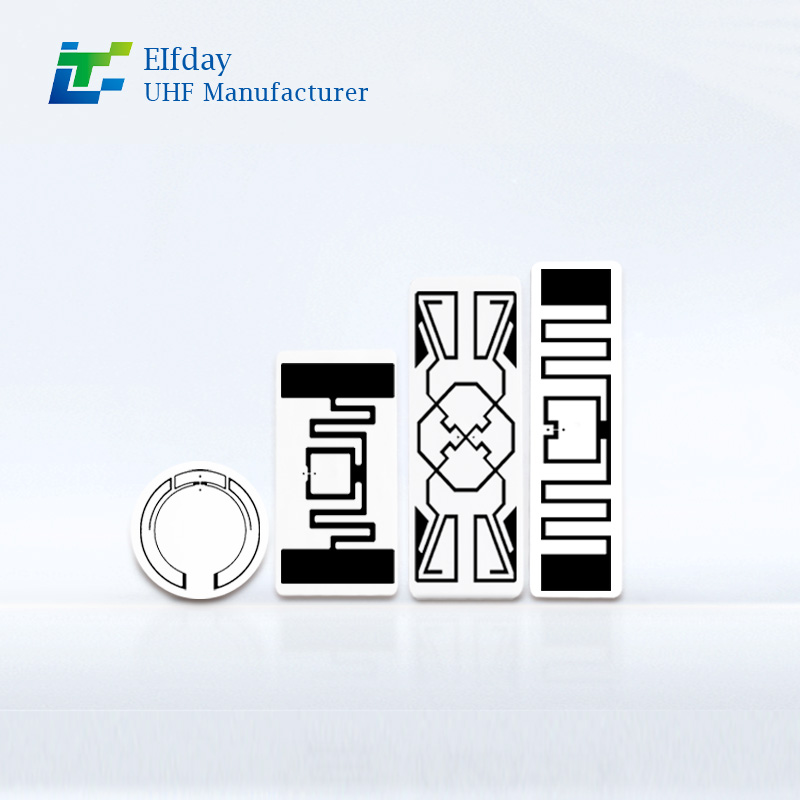

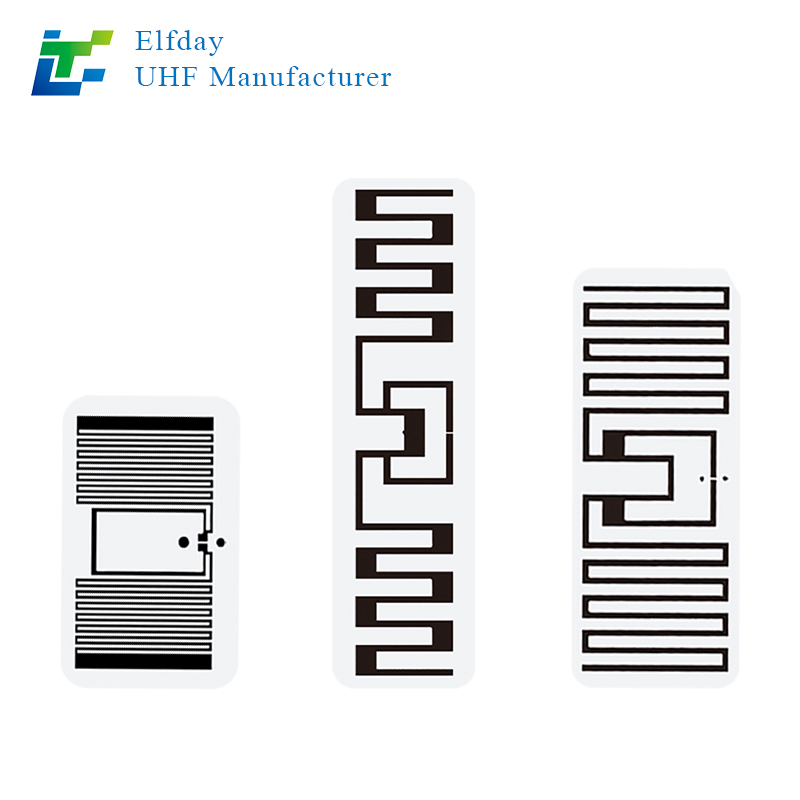

RFID tags are small electronic devices that use radio waves to transmit data to a reader. In logistics, they are attached to items, pallets, or containers, providing critical information such as location, condition, and movement. Unlike traditional barcode systems, RFID tags do not require direct line-of-sight to be read, making them ideal for fast-paced and large-scale environments like warehouses and distribution centers.

Key Benefits of RFID Tags for Logistics

1. Enhanced Inventory Management

One of the biggest challenges in logistics is maintaining accurate inventory records. Traditional manual systems or barcode scanners can be time-consuming and prone to human error. RFID tags provide real-time data, ensuring that inventory levels are always up-to-date. This leads to reduced stockouts, minimized overstocking, and improved demand forecasting.

2. Real-Time Tracking and Visibility

With RFID tags, logistics companies can track goods from the point of origin to the final destination. This real-time tracking capability provides increased visibility throughout the supply chain. Customers can also benefit from knowing exactly where their products are, which enhances customer satisfaction and builds trust.

3. Faster Shipping and Receiving

RFID tags significantly speed up the shipping and receiving process. Warehouse workers no longer need to scan each item individually. Instead, RFID readers can automatically detect and log multiple items in seconds, reducing processing times and improving overall efficiency.

4. Reduced Operational Costs

By automating inventory and tracking processes, RFID technology helps logistics companies cut down on labor costs and human errors. Fewer errors lead to fewer returns and disputes, which translates to lower operational costs and higher profitability.

5. Improved Security

RFID tags can be equipped with encrypted data, providing an added layer of security for valuable or high-risk items. The ability to track assets in real-time also reduces the risk of theft or misplacement during transportation.

Applications of RFID Tags in Logistics

Inventory Control: RFID tags are used to track raw materials, finished goods, and everything in between, allowing for accurate and efficient inventory management.

Fleet Management: RFID tags help track the location of vehicles, ensuring timely deliveries and reducing downtime.

Asset Tracking: From tools to heavy machinery, RFID can be used to monitor the location and usage of assets within a warehouse or distribution center.

Cold Chain Management: RFID tags with temperature sensors are used to monitor the condition of perishable goods during transportation, ensuring they stay within optimal temperature ranges.

Why RFID Tags Are a Game Changer for Logistics

As logistics companies strive to keep up with global demand and complex supply chains, embracing technology like RFID is no longer optional—it’s essential. RFID tags provide a scalable solution that enhances visibility, boosts operational efficiency, and ultimately delivers a competitive edge in an increasingly digital world.

For businesses looking to stay ahead of the curve, integrating RFID tags into logistics operations is a step towards future-proofing their supply chains and ensuring that they meet the demands of the modern market.

RFID tags are revolutionizing the logistics industry by offering unmatched efficiency, visibility, and cost savings. Whether you're a logistics provider or a business looking to optimize your supply chain, the integration of RFID technology is a smart investment that will deliver long-term benefits.