Why UHF RFID Tags Are a Must-Have for Modern Warehouses

In today’s fast-paced logistics and warehousing industry, efficiency is everything. With inventory management being a critical factor in operations, modern warehouses are increasingly adopting cutting-edge technology to streamline processes. One such technology that’s revolutionizing warehouse operations is UHF RFID tags (Ultra High-Frequency Radio Frequency Identification).

If you're looking to enhance your warehouse operations, improve accuracy, and optimize your supply chain, UHF RFID tags should be at the top of your list. Here's why they are a must-have for any modern warehouse.

What Are UHF RFID Tags?

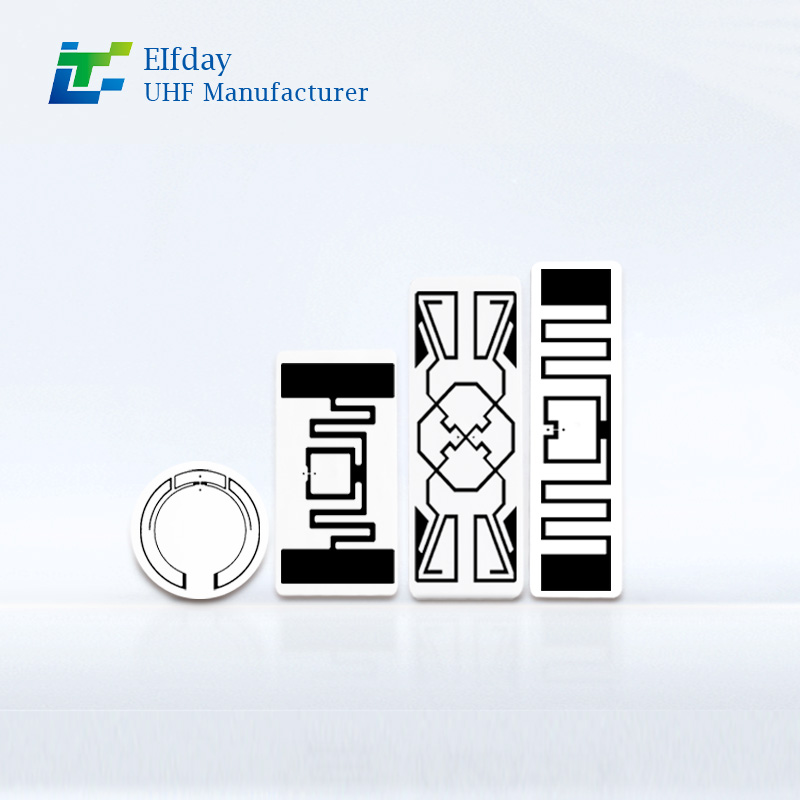

UHF RFID tags are small, durable devices that utilize radio waves to communicate with RFID readers. The "UHF" in UHF RFID stands for Ultra High Frequency, which is the frequency range that these tags operate within—usually between 860 and 960 MHz. UHF RFID tags are used for tracking and managing inventory in warehouses, ensuring real-time visibility of goods as they move through the supply chain.

Increased Efficiency in Inventory Management

One of the key benefits of UHF RFID tags is their ability to dramatically improve inventory management. Unlike traditional barcode systems, which require line-of-sight scanning, RFID tags can be read remotely, without needing to be in direct view of the reader. This makes inventory tracking much faster and more accurate, reducing the chances of human error.

With UHF RFID tags, warehouses can track the movement of products as they enter, exit, and are stored within the facility. This real-time visibility allows warehouse managers to instantly know where items are located, which significantly speeds up the inventory management process.

Streamlined Operations and Labor Savings

Implementing UHF RFID tags can significantly reduce the amount of time spent on manual inventory counts. Traditional barcode scanning is time-consuming and labor-intensive, especially when handling large quantities of goods. RFID technology, on the other hand, allows employees to scan entire pallets of products at once, improving efficiency and cutting down on labor costs.

In addition, RFID-enabled systems can trigger automatic alerts when stock levels are low, helping to prevent stockouts and overstocking—two issues that can disrupt the smooth running of warehouse operations.

Enhanced Accuracy and Reduced Errors

One of the most significant challenges in warehouse management is minimizing errors. Human mistakes, such as scanning the wrong barcode or misplacing products, can lead to costly delays and inventory discrepancies. UHF RFID tags reduce the risk of such errors because they provide a more automated and reliable way to track inventory. Each RFID tag has a unique identifier that ensures accuracy when scanning, significantly decreasing the likelihood of misplaced or miscounted goods.

Better Asset Tracking and Loss Prevention

UHF RFID tags are also an excellent solution for asset tracking and loss prevention in warehouses. With RFID technology, you can track valuable assets like machinery, tools, and high-value inventory at all times. This helps prevent theft, misplacement, or loss of critical equipment, which can otherwise lead to downtime and lost revenue.

Furthermore, RFID tags can provide detailed information about the condition and location of assets, allowing for more proactive maintenance and management.

Scalability and Flexibility

As your business grows, so do your inventory needs. UHF RFID tags offer scalability, making them a future-proof solution for expanding warehouses. Whether you’re adding new products to your warehouse or expanding to new locations, RFID technology can easily adapt to your evolving needs. The system can be tailored to track various types of goods, from small parts to large machinery, ensuring you stay ahead of the competition.

Why Choose UHF RFID Tags Over Other Options?

While there are other types of RFID tags available (such as LF and HF RFID), UHF RFID tags offer several distinct advantages that make them ideal for warehouse environments. Their longer read range and faster data transfer speeds make them perfect for large-scale warehouse operations. Unlike Low-Frequency (LF) or High-Frequency (HF) RFID systems, UHF systems can read tags at distances of up to 10 meters, significantly increasing operational efficiency.

Additionally, UHF RFID tags are highly durable and resistant to wear and tear, making them suitable for harsh warehouse environments. Whether exposed to extreme temperatures, moisture, or heavy-duty handling, these tags are designed to last.

How UHF RFID Tags Drive ROI

Investing in UHF RFID tags doesn’t just improve operational efficiency—it also offers a significant return on investment (ROI). By reducing labor costs, improving accuracy, minimizing errors, and enhancing inventory visibility, RFID systems ultimately save your business money. The cost savings gained through faster processing, fewer stock discrepancies, and improved loss prevention can easily outweigh the initial setup costs.

Incorporating UHF RFID tags into your warehouse operations is no longer just an option; it’s a necessity for modern, efficient inventory management. Whether you’re aiming to reduce costs, improve accuracy, or enhance operational visibility, RFID technology offers the solution.

For warehouses looking to stay competitive in an increasingly digital world, adopting UHF RFID tags is a step toward achieving greater efficiency, scalability, and profitability. Don’t get left behind—make the smart choice for your warehouse today!